Before starting my graduate education, I worked as a CNC machinist and programmer, operating 3-and-5 axis wood, metal and plastic milling machines. I was responsible for the programming and fabrication of several projects - from gallery installations to restaurant buildouts. I continued this work upon coming to Harvard, becoming the head CNC milling teaching assistant in the GSD Fabrication Lab, responsible for programming student work, safe machine operation and tool maintenance. The type of work changed in an academic setting, becoming more focused on architectural models and conceptual projects. I believe that operating and understanding these machines has given me unique insight into the processes of realizing design intention, directly from the digital to the material.

Any CNC machining process is not automatic - it requires specific knowledge about the tools used, the intended materials and the machine itself. Working with the Fabrication Lab for four years gave me valuable teaching experience, leading a series of classes on the process of bringing a project from a digital 3D model in Rhino to programming in MasterCAM to executing the job on a specific machine. I was also responsible for training new CNC TA's on proper machine processes and operation.

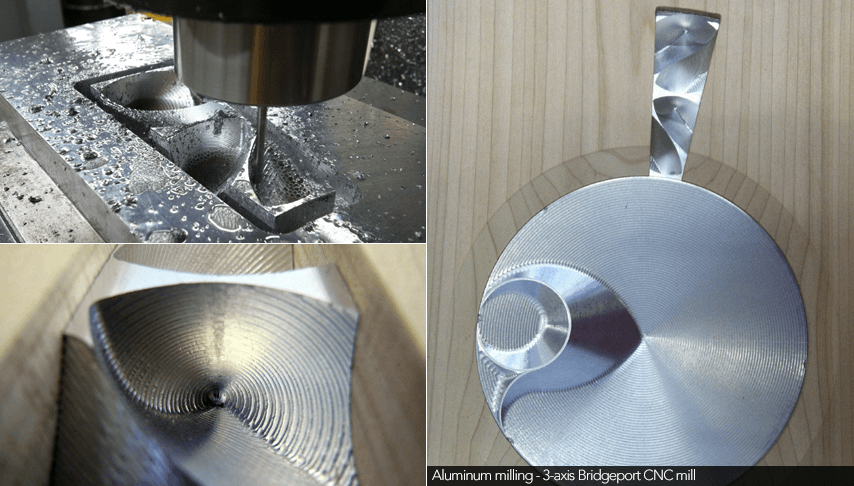

Shown here are selected examples of personal, academic and professional work created partially or entirely through CNC machining processes. From exhibitions to architectural installations to furniture, I personally designed, programmed, milled and assembled all of these projects.